Production process

PRODUCTION PROCESS

Sourcing - Brass is sourced from the most reputed vendors and is inspected by its QC staff before it is sent for casting.

Casting - Virgin brass and scrap is casted in various moulds as per the pattern using the Gravity Die Casting process. Burnt cores are the meticulously removed from the cast products.

Machining - Casted products are machined as per the design requirements to create threads.

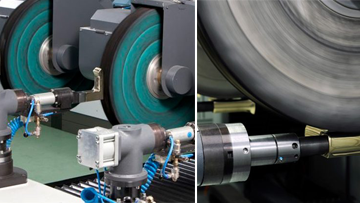

Grinding/Polishing - The machined product is thus grinded using belt grinders to achieve smooth finishes without sharp edges. The grinded pieces are polished on high speed polishing machines by experienced workers to achieve perfect surface with high glass and sheen.

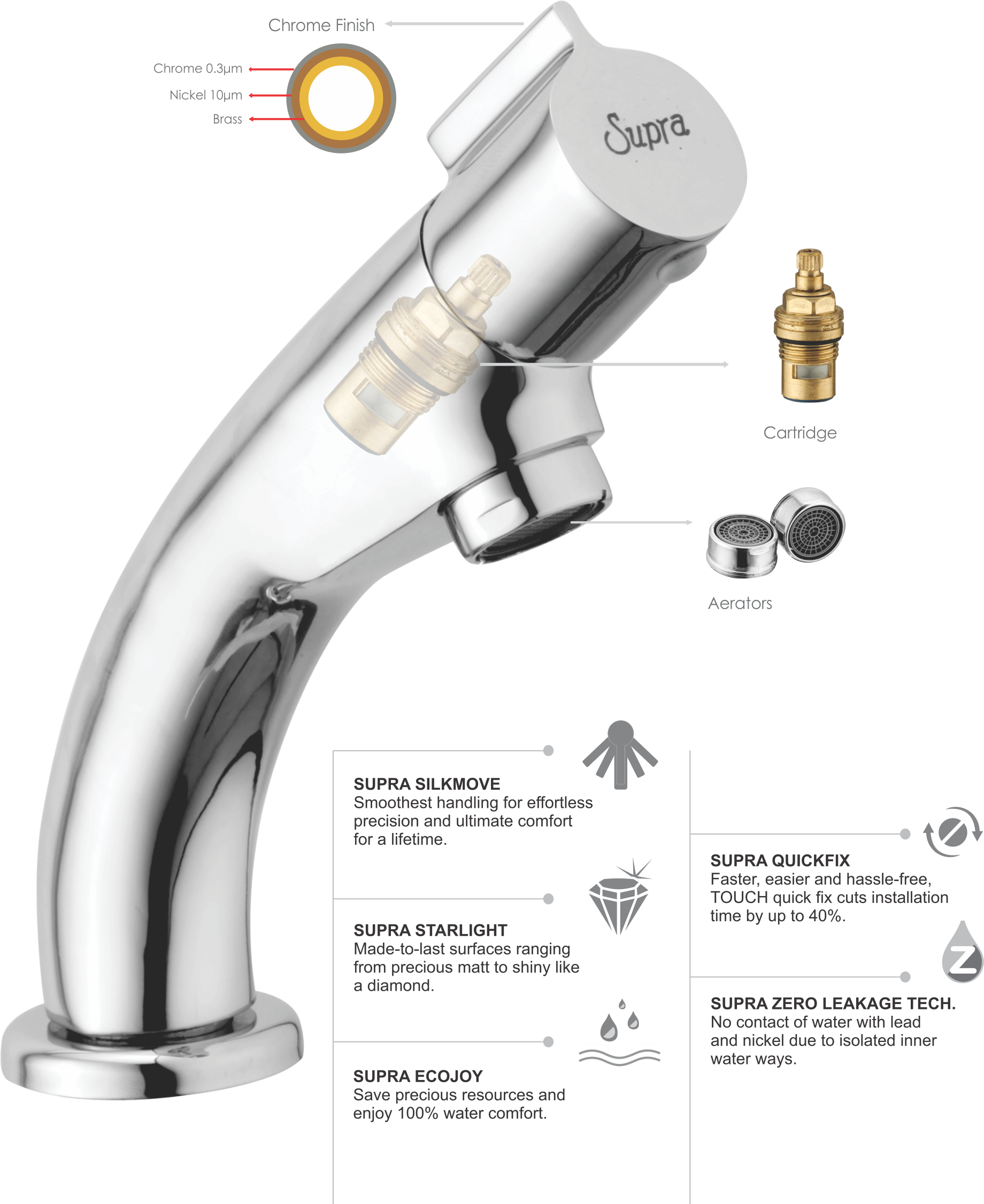

Finishing - The tested and okayed pieces are then undergo the process of finishing and chroming.

Testing - Having undergone the above processes, the pieces are then meticulously checked for surface defects. The water carrying components are pressure tested using Hydraulic Testing Machines at a pressure of 50 to 100 PSI to detect any leakage in the casting.

Assembly - The coated pieces are assembled as per the requirements.

The tested and approved pieces are then packed in corrugated colour boxed that go into jute lined corrugated boxes. The packed goods are then subject to the random checking by the management.